SafeWind

Rope winder monitoring system

Introduction

SAFEWIND® is a rope winder monitoring system that records, analyses and supervises signalling and other aspects of safe operations, and can proactively intervene to avert danger.

Functions

Bell recording and interpretation

When SAFEWIND® is set up, all bell signal patterns are recorded on a database. In the live environment, the expected bell sequences are compared to the actual signals received, allowing the system to monitor direction of travel. If the bell sequences deviate from those expected or from the correct timing, the system can produce an alarm condition, in accordance with the client’s specifications: warning, exception or critical, or any combination thereof. Thus the correct direction of travel is always applied and any drum malfunction is identified early.

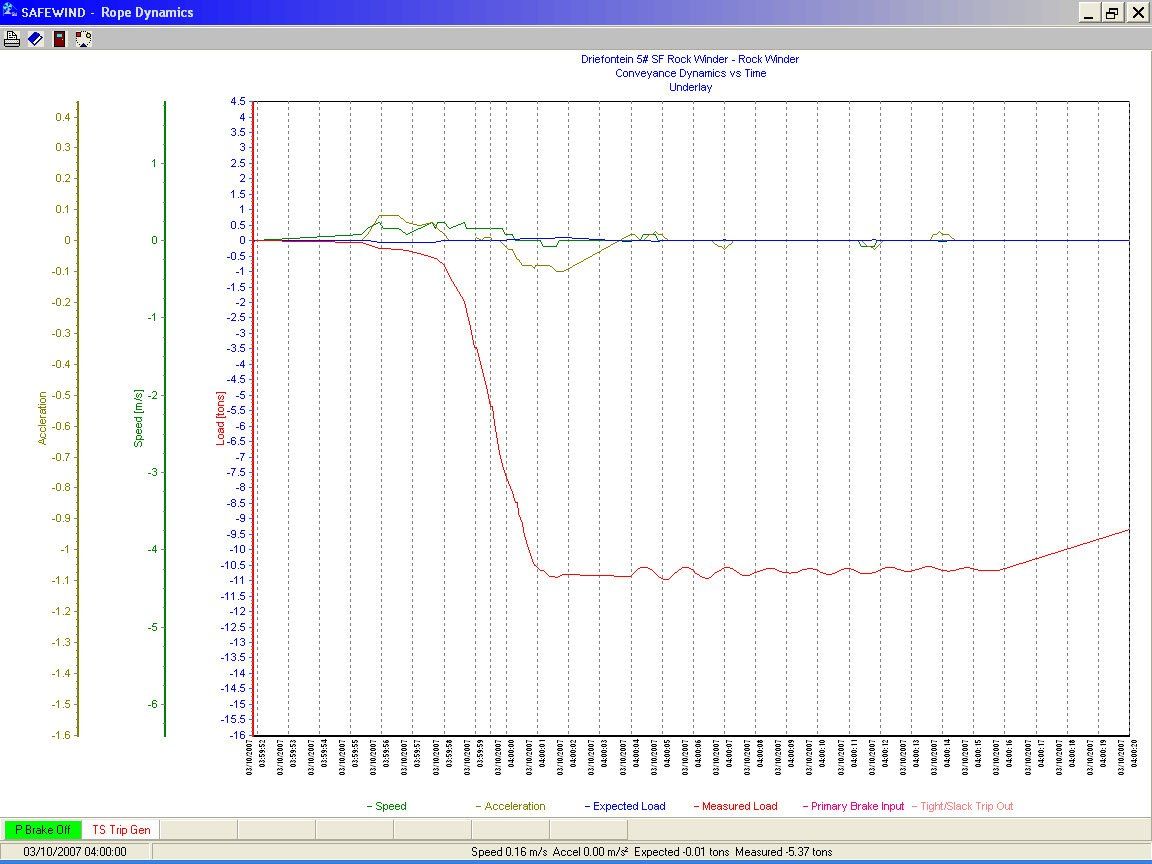

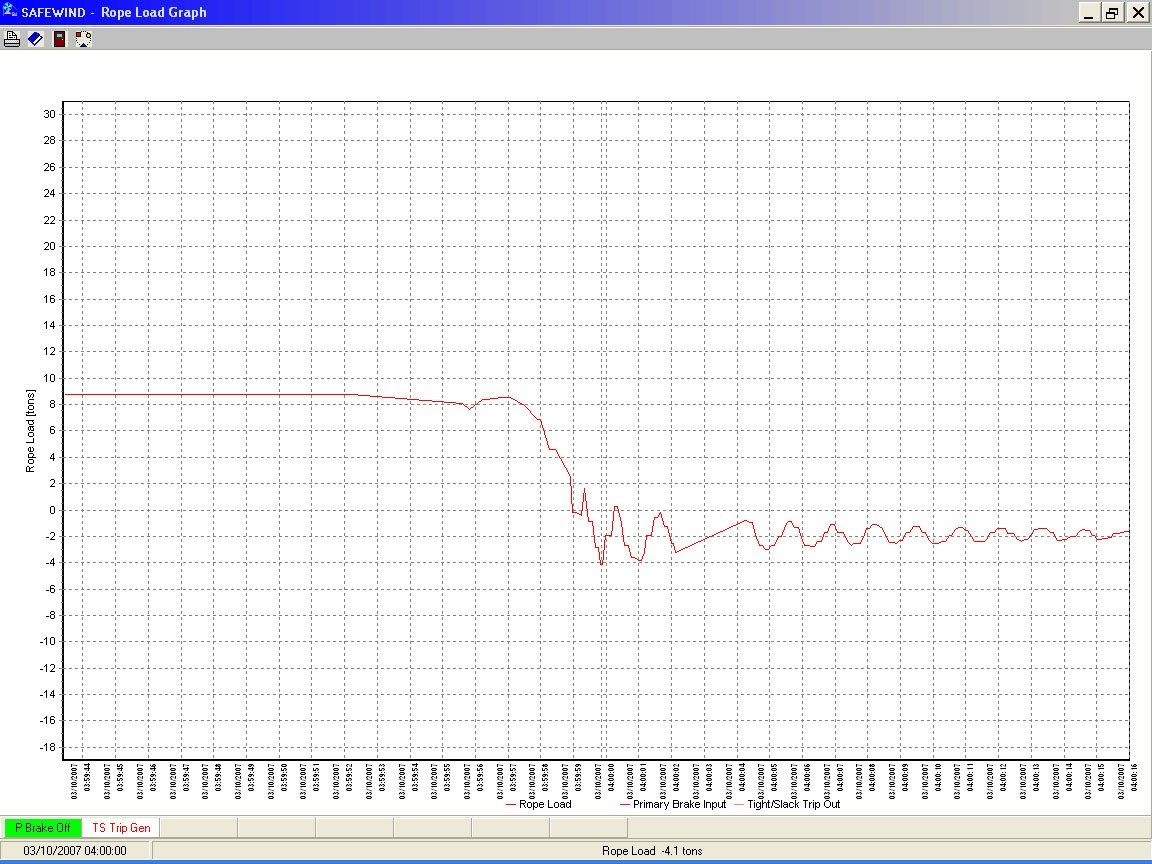

Continuous tight and slack monitoring

The Continuous Tight and Slack Rope system regularly measures rope load against a predetermined value and trips the rope or alarms the driver when the deviation exceeds a pre-set limit, ensuring maximum safety is maintained. Rope load is sensed using strain gauge transducers and signals are amplified into voltage signals which are captured by the SAFEWIND® Data Acquisition Unit.

Technical Specifications

Master Unit

| Hardware Platform | Intel Celeron Computer minimum 2Gigabyte processor 120 Gbyte Hard-disk memory, LCD 19 inch |

|---|---|

| Software Operating System | WINDOWS XP Professional |

| Cycle Time | 2 milliseconds max - typically 1 ms |

Slave Unit - Processor System

| Hardware Platform | Single Board Industrial Controller complete with 2 gigabyte compact flash. LCD 15 inch |

|---|---|

| Cycle Time | Typically 1 milliseconds |

| Response Time | Typically 2 milliseconds |

| Digital Inputs | Maximum 96 |

| Digital Outputs | Maximum 8 |

| Timer | Resolution 100us - accuracy 10ppm |

| Distance Measurement (Notes) | 1 part in 500 of the nominal drum diameter. Typically 0.25% of the drum circumference |

| Speed Measurement (Notes) | Better than 0.05 m/s actual rope speed. Typically 0.5% of maximum speed |

| Acceleration Measurement (Notes) | Better than 0.1 m/s2 actual rope acceleration. Typically 1% of maximum acceleration |

| Storage Capacity | User defined on a wrap around basis. Maximum - 60 days with 2 Gigabyte Compact flash |

| Communications | RS232/RS485 115200 Baud Rate |

| Operator Interface | Monitor 15 inch |

| Configuration | Via master system only using serial communication link |

Notes

- Using an encoder with a resolution of 500 pulses per revolution of the drum

- Includes compensation for the rope thickness, number of coils per layer and the starting number of coils on the top layer

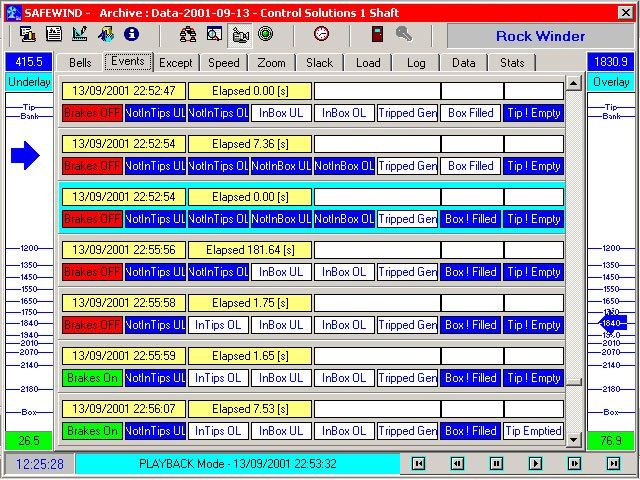

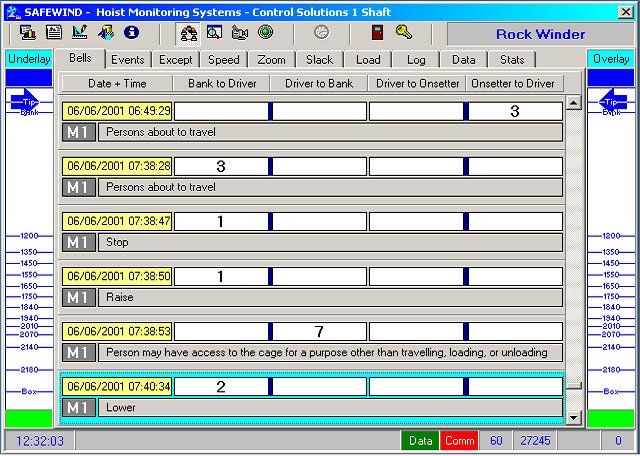

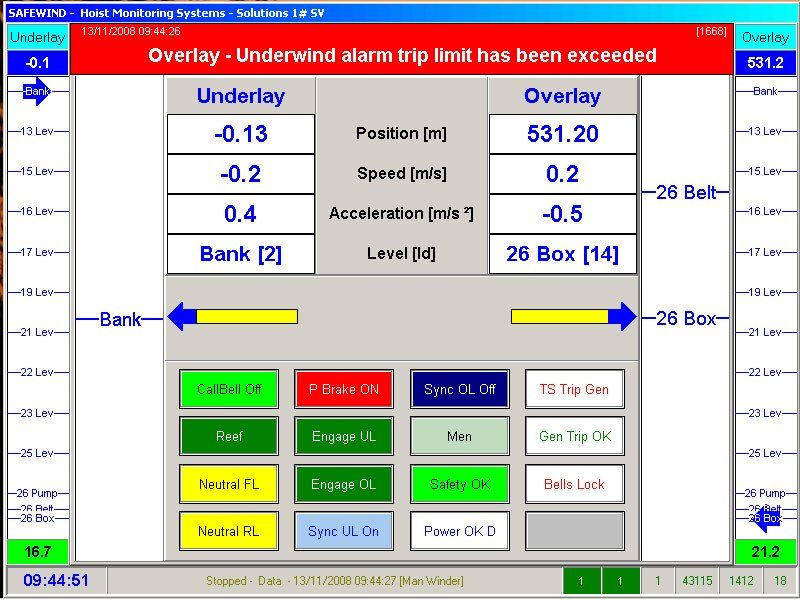

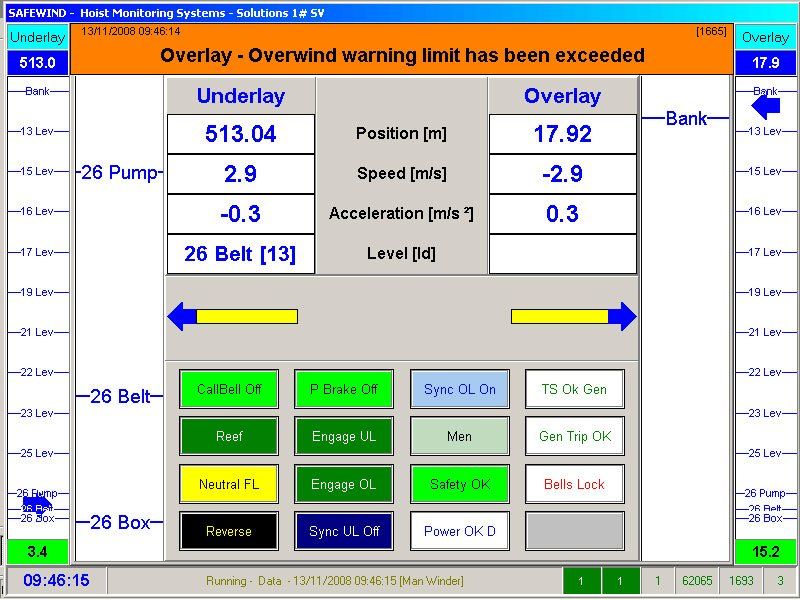

SafeWind Screenshots

Bell recording and interpretation

When SAFEWIND® is set up, all bell signal patterns are recorded on a database. In the live environment, the expected bell sequences are compared to the actual signals received, allowing the system to monitor direction of travel. If the bell sequences deviate from those expected or from the correct timing, the system can produce an alarm condition, in accordance with the client’s specifications: warning, exception or critical, or any combination thereof. Thus the correct direction of travel is always applied and any drum malfunction is identified early.

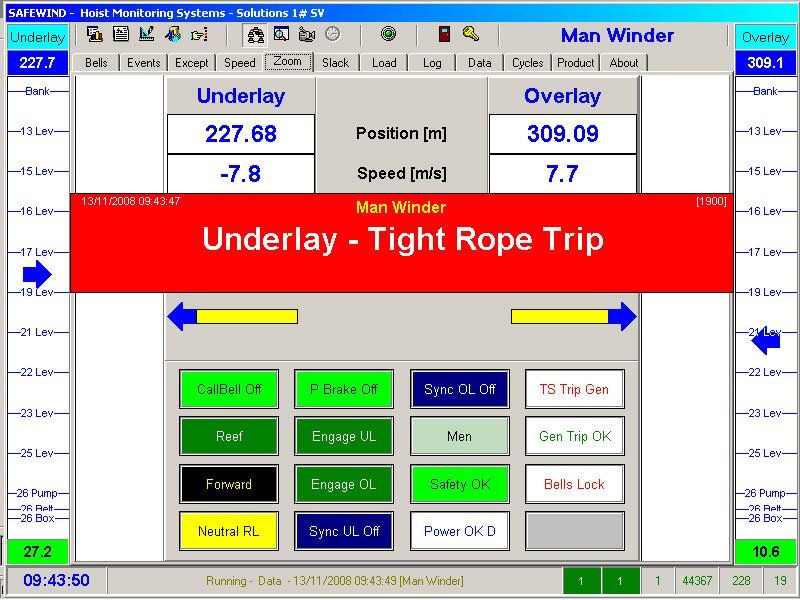

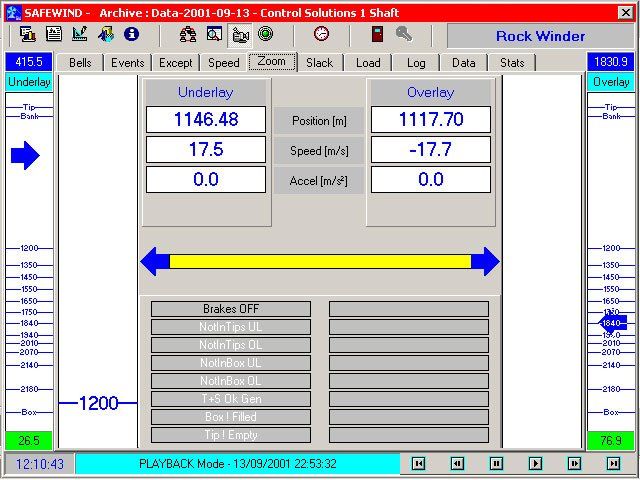

Continuous tight and slack monitoring

The Continuous Tight and Slack Rope system regularly measures rope load against a predetermined value and trips the rope or alarms the driver when the deviation exceeds a pre-set limit, ensuring maximum safety is maintained. Rope load is sensed using strain gauge transducers and signals are amplified into voltage signals which are captured by the SAFEWIND® Data Acquisition Unit.

Downloads

Return to: